CONNECT TO COLLABORATE

A network of concepts and objects, leading to higher level actions

Products

Our WiFi/I-IoT enabled RFID Reader, and Barcode Scanner can track objects at each point of process flow. Like apparels can be tracked during cutting, sewing, and packing. pluGence devices can be paired with any generic wifi-routers to transport the data from these scanners to your existing ERP/MIS and/or cloud. IoT Switch-board can control any electrical gadget remotely either by sensors or by mobile-app

Opportunities

Track objects at point of process. Control equipment based on live parameters. Control emission of excessive gas and chemicals. Save a lot of manual energy by way of autmoating data transport to your back-end. Avoid wasteful expenses with coordinated use of scarce resources like water, electricity etc. High data-integrity and accuracy. Streamlined production line.

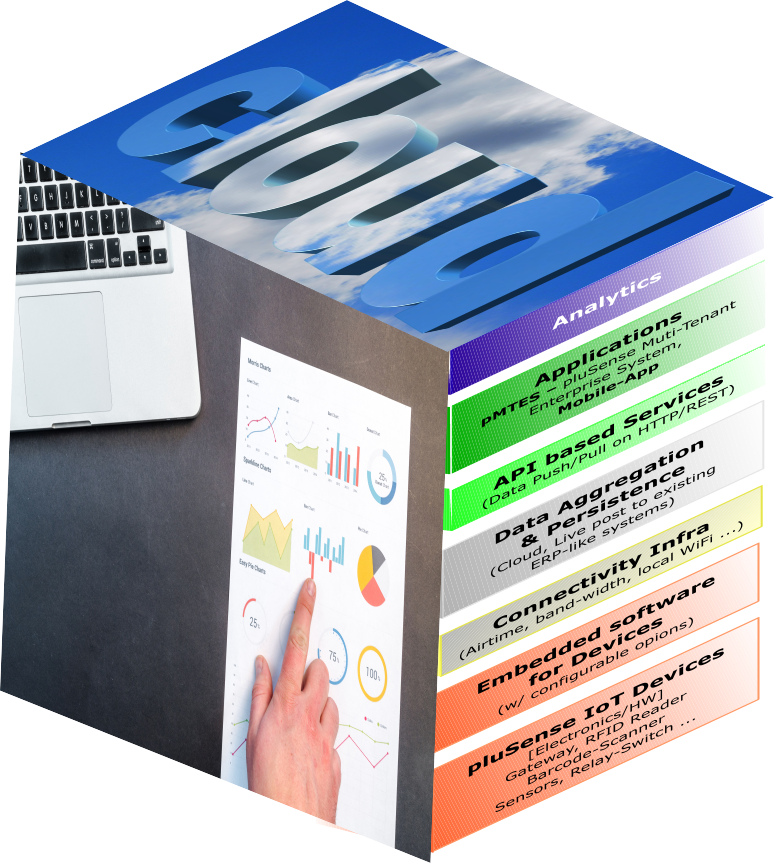

Our Solution

Tagged (RFID/Barcode) objects are tracked till they go out of inventory. Produce ready-to-process accurate data. Count indication at Counter Device, of the objects being moved out in a section/point-of-process. Seamless data transport to your ERP/MIS. Optional multi-tenant cloud applications to manage devices and data. All pluGence devices are configurable from mobile-app and cloud. No manual intervention.

Benefits

Repetitive, boring and error-prone operations are automated. Data gathered is directly pushed into your ERP/MIS and cloud. Data is ready-to-process for dependent applications. Use of high-end technology. Your business becomes IoT enabeld. Data redundancy is avoided. Highly configurable to meet typical manufacturing industry like garments/textile.